Our Robots

Featured Robot

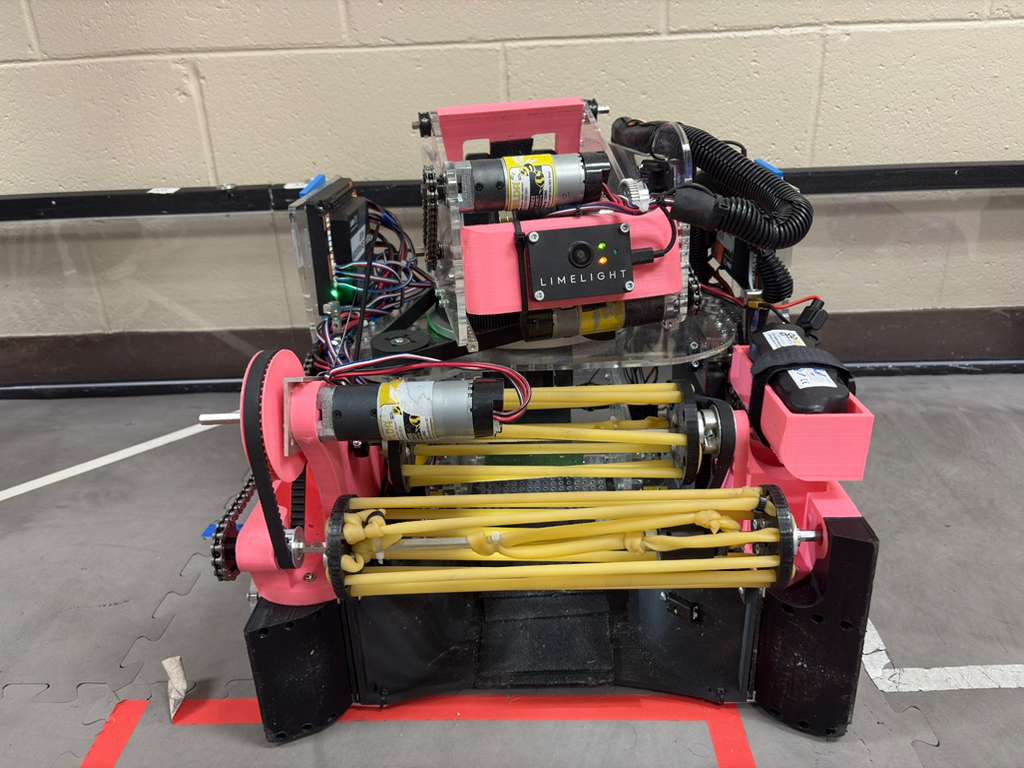

Ghost Rider

Season: Decode 2026

This robot was designed with a strong focus on innovation and automation to reduce pressure on the drivers during competition. Through unique engineering ideas and thoughtful system integration, we aimed to create a robot that is consistent, efficient, and capable of performing complex tasks reliably.

Robot Highlights

Adjustable Hood

Allows precise control over shot trajectory, improving scoring consistency across different field positions and distances.

Automatic AprilTag Detection

Uses vision processing to automatically detect field markers, enabling faster alignment and more reliable autonomous and assisted actions.

Limelight-Integrated Turret

Combines vision data with turret control to continuously track targets, reducing driver workload and improving accuracy under pressure.

Surgical Tubing Intake

Designed for compliant and efficient object acquisition, helping maintain intake reliability while minimizing jams and misalignment.

Subsystem Breakdown

Drivetrain

Our robot uses a mecanum drivetrain mounted on a custom laser-cut chassis designed to reduce overall weight while optimizing the robot’s footprint for our specific design goals. The chassis geometry was intentionally engineered to enhance precision and stability, allowing for smoother movement and more predictable handling.

By reducing unnecessary mass and tightening the drivetrain layout, we were able to improve responsiveness and minimize driver error during both manual control and automated actions. This design choice supports accurate alignment and consistent positioning throughout a match.

Intake & Outtake System

Our intake and outtake system is a three-stage mechanism designed to maintain control of game pieces throughout the entire transfer process. Balls move sequentially through each stage to ensure consistent orientation and timing before scoring.

The first two stages use surgical tubing to provide compliant, reliable intake and transport. This allows the system to handle misaligned game pieces while minimizing jams and maintaining steady acquisition during fast-paced gameplay.

In the final stage, gecko wheels are used to intentionally slow the balls before they reach the 3D-printed flicker. By reducing speed at this point, the system improves consistency and accuracy when releasing game pieces into the turret, resulting in more controlled and repeatable scoring.

Scoring Mechanism

The scoring mechanism is designed as an integrated system that prioritizes accuracy, timing, and automation. At the end of the three-stage intake and outtake system is a 3D-printed flicker driven by Axon servos, which precisely controls when game pieces are released toward the turret.

The flicker moves forward to feed game pieces into the turret and retracts to hold balls securely in place between scoring cycles. This controlled motion ensures consistent timing and reduces variability during high-pressure match situations.

The turret uses Limelight vision to continuously detect AprilTags and maintain an active lock on the goal. Paired with an adjustable hood that dynamically increases or decreases its angle based on distance from the target, the system enables accurate and repeatable scoring from multiple field positions while minimizing driver intervention.